|

|

Diesel Fuel Injection Pump Test Benches with Mechanical Variable Speed Drive |

| Features: - Mechanical Variable Speed Drive with the help of expandable compound pulley system and dual belt fitting with standard drive shaft coupling - Shaft Bearing, self aligning, self lubricating, totally enclosed - Oil Supply made by Hydraulic Gear Pump driven by a 1.0 HP motor - Electronic Digital Tachometer, 0 - 9999 RPM with accuracy of ± 1 RPM - Electronic Multi Strokes 100 - 1200 in steps of 100 strokes - Injector Nozzles at 175 kg/cm2 pressure - Pressure phasing recorded on the degree dial - Fuel Tank Capacity: 45 to 50 liters - Pressure gauge of 0-100 PSI (0-7 kg./cm2) and 0-500 PSI (0-35 kg./cm2) - Measuring panel can be swiveled on either side at 180o for right and left hand pumps |

Functions: - Pump and Gallery Leakage Testing - Checking Coupling Timing Mark - Phasing the Pump - Calibrating (Flow Testing) the output of each element of the pump - Setting the Pump for Maximum Output - Complete Cut-off - Checking of Governor and Feed Pump Testing |

Model: SD-8 |

|

|

Specifications:

|

| Standard

Accessories: One set mounting bracket and quick action clamp for

in-line (camshaft) pumps, 8 / 12 High Pressure Pipes with M12 x 1.5 and M14

x 1.5 union nuts, 8 / 12 High Pressure Pipes with M14 x 1.5 union nuts both

ends, one set graduated glass test tubes, one flange type bracket for pump

mounting, one phasing bar, one machine lamp, set of perforated trays for

keeping tools, back lash free flexible coupling, wooden drawer for keeping

hand tools, digital electronic voltmeter, flexible pipes for pump connection Optional Accessories: Attachment for Rotary, CAV & DPA pumps, In-Line fuel pump tool kit |

|

|

Diesel Fuel Injection Pump Test Benches with Hydraulic Variator Drive |

| Features: - Hydraulic Variator Drive - Shaft Bearing, self aligning, self lubricating, totally enclosed - Oil Supply made by Hydraulic Gear Pump driven by a 1.0 HP motor - Electronic Digital Tachometer, 0 - 9999 RPM with accuracy of ± 1 RPM - Electronic Multi Strokes 100 - 1200 in steps of 100 strokes - Injector Nozzles at 175 kg/cm2 pressure - Pressure phasing recorded on the degree dial - Fuel Tank Capacity: 45 to 50 liters - Pressure gauge of 0-100 PSI (0-7 kg./cm2) and 0-500 PSI (0 - 35 kg./cm2) - Measuring panel can be swiveled on either side at 180o for right and left hand pumps |

Functions: - Pump and Gallery Leakage Testing - Checking Coupling Timing Mark - Phasing the Pump - Calibrating (Flow Testing) the output of each element of the pump - Setting the Pump for Maximum Output - Complete Cut-off - Checking of Governor and Feed Pump Testing |

Model: SD-8/HV |

|

|

Specifications:

|

| Standard

Accessories: One set mounting bracket and quick action clamp for

in-line (camshaft) pumps, 8 / 12 High Pressure Pipes with M12 x 1.5 and M14

x 1.5 union nuts, 8 / 12 High Pressure Pipes with M14 x 1.5 union nuts both

ends, one set graduated glass test tubes, one flange type bracket for pump

mounting, one phasing bar, one machine lamp, set of perforated trays for

keeping tools, back lash free flexible coupling, wooden drawer for keeping

hand tools, digital electronic voltmeter, flexible pipes for pump connection Optional Accessories: Attachment for Rotary, CAV & DPA pumps, In-Line fuel pump tool kit |

| Diesel Fuel Injection Pump Test Benches with A/C Frequency Drive |

| Features: - A/C Frequency Drive - Shaft Bearing, self aligning, self lubricating, totally enclosed - Oil Supply made by Hydraulic Gear Pump driven by a 1.0 HP motor - Electronic Digital Tachometer, 0 - 9999 RPM with accuracy of ± 1 RPM - Electronic Multi Strokes 100 - 1200 in steps of 100 strokes - Injector Nozzles at 175 kg/cm2 pressure - Pressure phasing recorded on the degree dial - Fuel Tank Capacity: 45 to 50 liters - Pressure & Vacuum gauge of 0-100 PSI (0-7 kg./cm2), 0-500 PSI (0-35 kg./cm2), 0-200 PSI (0-14 kg/cm2) & 0-30 in/Hg (0-760 mm/Hg) - Measuring panel can be swiveled on either side at 180o for right and left hand pumps |

Functions: - Pump and Gallery Leakage Testing - Checking Coupling Timing Mark - Phasing the Pump - Calibrating (Flow Testing) the output of each element of the pump - Setting the Pump for Maximum Output - Complete Cut-off - Checking of Governor and Feed Pump Testing |

Model: SD-8/ACD |

|

|

Specifications:

|

| Standard

Accessories: One set mounting bracket and quick action clamp for

in-line (camshaft) pumps, 8 / 12 High Pressure Pipes with M12 x 1.5 and M14

x 1.5 union nuts, 8 / 12 High Pressure Pipes with M14 x 1.5 union nuts both

ends, one set graduated glass test tubes, one flange type bracket for pump

mounting, one phasing bar, one machine lamp, set of perforated trays for

keeping tools, back lash free flexible coupling, wooden drawer for keeping

hand tools, digital electronic voltmeter, flexible pipes for pump connection Optional Accessories: Attachment for Rotary, CAV & DPA pumps, In-Line fuel pump tool kit |

|

|

|

Cummins Pump Test Bench |

|

- MODEL: CTB-5 Optional: Heating (2 kW) with digital temperature controller 0 - 200 degrees centigrade which can be preset to predetermined temperature with auto cut thermal cutout - electronically operated |

|

Cummins Injector Calibrator |

- MODEL: CIC-5 Optional: Heating (2 kW) with digital temperature controller 0 - 200 degrees centigrade which can be preset to predetermined temperature with auto cut thermal cutout - electronically operated |

|

|

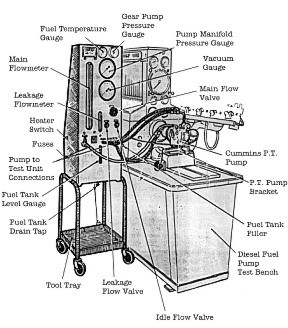

Mobile Test Stand for Cummins PT Pumps |

|

MODEL: CTS-M

Net / Gross Weight (Kgs.): 60 / 100 |

|

| Injector Leakage Tester |

|

- MODEL: CILT-150 Net / Gross Weight (Kgs.): 50 / 90 |

|

Maneklal Global Exports |

|

TO OUR PAGE ON AUTOMOTIVE ENGINE REBUILDING MACHINES |