|

|

| Three Roll Pinch Pyramid Plate Bending Machines | Motorized Heavy Duty Bending Rollers | Motorized Light Duty Bending Rollers | Hand Operated Bending Rollers - Slip Type | Taper Bending Rollers |

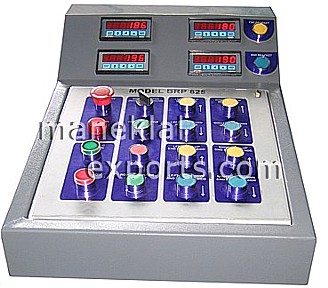

Model: BRP-825 |

|

|

- The machine incorporates a fixed

top roll & two independently adjustable bottom rolls. |

|

|

- The machine frame is all steel welded construction. - Drive to the machine is a combination of electromechanical drive with oil cooled gearbox & hydraulic power pack for movement of Bottom Rolls and Swing down bracket for easy removal of the shell. The swing down bracket is hydraulically operated. - For conical bending, bottom rolls can be tilted and cone can be formed. - Rolls are made from EN-8 Forged Steel and are ultrasonically tested. - Machine has a semi-centralized lubrication system. - Working capacity of the machine is based on plate tensile strength of 45 Kg/mm2. - Adequate overload protection with relays and limit switches. - Centralized push button control panel with interlocked circuits. - Electromagnetic brake system for accurate Edge positioning. - Roller positioning indicator. |

|

|

| Specifications: |

| Model: | BRP-812 | BRP-820 | BRP-825 | BRP-840 | BRP-850 | BRP-1012 | BRP-1020 | BRP-1025 | BRP-1030 | BRP-1040 | BRP-1050 |

| Pre-Pinching / Pre-Bending Capacity (mm) | 12 x 2500 | 20 x 2500 | 25 x 2500 | 40 x 2500 | 50 x 2500 | 12 x 3000 | 20 x 3000 | 25 x 3000 | 30 x 3000 | 40 x 3000 | 50 x 3000 |

| Rolling Capacity 3 x Top Roll Diameter (mm) | 16 x 2500 | 25 x 2500 | 30 x 2500 | 45 x 2500 | 55 x 2500 | 16 x 3000 | 25 x 3000 | 30 x 3000 | 36 x 3000 | 50 x 3000 | 55 x 3000 |

| Top Roll Diameter (mm) | 300 | 330 | 360 | 440 | 500 | 320 | 360 | 420 | 480 | 530 | 600 |

| Bottom Roll Diameter (mm) | 270 | 310 | 320 | 400 | 480 | 300 | 320 | 390 | 460 | 500 | 580 |

| Main Motor (HP): | 10 + 10 | 15 + 15 | 20 + 20 | 25 + 25 | 30 + 30 | 10 + 10 | 20 + 20 | 25 + 25 | 25 + 25 | 30 + 30 | 40 + 40 |

| Aux. Motor (HP): | 5 | 10 | 10 | 15 | 20 | 5 | 10 | 15 | 15 | 20 | 30 |

| Net Weight (kg): | 10000 | 13000 | 16000 | 22000 | 32000 | 12000 | 19000 | 24000 | 30000 | 40000 | 45000 |

| Dimensions (m): | 5.2 x 1.3 x 1.6 | 5.8 x 1.6 x 2.2 | 5.9 x 1.8 x 2.5 | 6.2 x 2.0 x 2.5 | 6.4 x 2.2 x 2.7 | 6.0 x 1.5 x 2.1 | 6.5 x 1.5 x 2.5 | 6.7 x 1.5 x 2.5 | 6.8 x 1.6 x 2.7 | 6.8 x 1.8 x 2.8 | 7.0 x 2.0 x 2.8 |

|

|

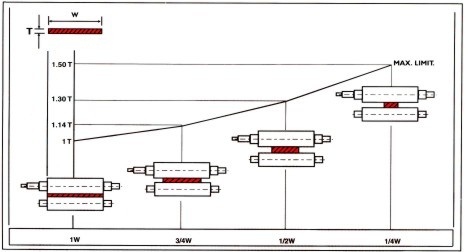

Plate Thickness (T) variation in accordance with the Rolling Width (W) |

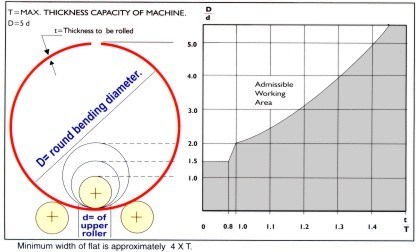

Plate Thickness (t) variation in accordance with the Round Bending Diameter (D) |

|

|

|

VIDEO OF THREE ROLL PINCH PYRAMID BENDING ROLLER MACHINE MODEL: BRP-825 - BENDING OPERATION |

|

VIDEO OF THREE ROLL PINCH PYRAMID BENDING ROLLER MACHINE MODEL: BRP-825 - PRE-PINCHING OPERATION |

|

- All steel fabrication housing |

|

Model: BR-30/25 |

Model: BR-25/16 |

| Model: | BR-12/3 | BR-12/6 | BR-12/10 | BR-12/12 | BR-12/16 | BR-12/20 | BR-12/25 |

| Cap. Width x Thickness (mm): | 1250 x 3 | 1250 x 6 | 1250 x 10 | 1250 x 12 | 1250 x 16 | 1250 x 20 | 1250 x 25 |

| Top Roll Diameter (mm): | 100 | 135 | 150 | 175 | 195 | 205 | 250 |

| Bottom Roll Diameter (mm): | 90 | 110 | 125 | 140 | 150 | 165 | 200 |

| Motor (HP): | 2.0 | 3.0 | 5.0 | 5.0 | 5.0 | 7.5 | 10.0 |

| Model: | BR-15/3 | BR-15/6 | BR-15/10 | BR-15/12 | BR-15/16 | BR-15/20 | BR-15/25 |

| Cap. Width x Thickness (mm): | 1500 x 3 | 1500 x 6 | 1500 x 10 | 1500 x 12 | 1500 x 16 | 1500 x 20 | 1500 x 25 |

| Top Roll Diameter (mm): | 120 | 150 | 180 | 190 | 200 | 215 | 260 |

| Bottom Roll Diameter (mm): | 105 | 125 | 140 | 150 | 160 | 170 | 200 |

| Motor (HP): | 3.0 | 5.0 | 7.5 | 7.5 | 10.0 | 12.5 | 15.0 |

| Model: | BR-20/3 | BR-20/6 | BR-20/10 | BR-20/12 | BR-20/16 | BR-20/20 | BR-20/25 | BR-20/30 | BR-20/36 |

| Cap. Width x Thickness (mm): | 2000 x 3 | 2000 x 6 | 2000 x 10 | 2000 x 12 | 2000 x 16 | 2000 x 20 | 2000 x 25 | 2000 x 30 | 2000 x 36 |

| Top Roll Diameter (mm): | 135 | 170 | 200 | 220 | 230 | 270 | 290 | 320 | 360 |

| Bottom Roll Diameter (mm): | 105 | 150 | 160 | 180 | 190 | 210 | 230 | 250 | 270 |

| Motor (HP): | 3.0 | 5.0 | 7.5 | 10.0 | 12.5 | 15.0 | 20.0 | 25.0 | 30.0 |

| Model: | BR-25/3 | BR-25/6 | BR-25/10 | BR-25/12 | BR-25/16 | BR-25/20 | BR-25/25 | BR-25/30 | BR-25/36 | BR-25/42 |

| Cap. Width x Thickness (mm): | 2500 x 3 | 2500 x 6 | 2500 x 10 | 2500 x 12 | 2500 x 16 | 2500 x 20 | 2500 x 25 | 2500 x 30 | 2500 x 36 | 2500 x 42 |

| Top Roll Diameter (mm): | 150 | 200 | 240 | 250 | 280 | 295 | 320 | 360 | 400 | 425 |

| Bottom Roll Diameter (mm): | 125 | 160 | 170 | 180 | 210 | 220 | 230 | 250 | 340 | 360 |

| Motor (HP): | 5.0 | 7.5 | 10.0 | 15.0 | 20.0 | 20.0 | 25.0 | 30.0 | 45.0 | 45.0 |

| Model: | BR-30/3 | BR-30/6 | BR-30/10 | BR-30/12 | BR-30/16 | BR-30/20 | BR-30/25 | BR-30/30 | BR-30/36 | BR-30/42 |

| Cap. Width x Thickness (mm): | 3000 x 3 | 3000 x 6 | 3000 x 10 | 3000 x 12 | 3000 x 16 | 3000 x 20 | 3000 x 25 | 3000 x 30 | 3000 x 36 | 3000 x 42 |

| Top Roll Diameter (mm): | 175 | 220 | 250 | 270 | 290 | 300 | 360 | 400 | 430 | 450 |

| Bottom Roll Diameter (mm): | 150 | 170 | 180 | 210 | 220 | 230 | 250 | 270 | 280 | 380 |

| Motor (HP): | 7.5 | 10.0 | 12.5 | 15.0 | 20.0 | 25.0 | 30.0 | 35.0 | 40.0 | 50.0 |

Model: BR-30/25 |

Model: BR-25/16 |

|

Standard Accessories: Electric motor and

starter |

|

VIDEO OF BENDING ROLLER MACHINE MODEL: BR-30/25 |

|

VIDEO OF BENDING ROLLER MACHINE MODEL: BR-25/16 |

|

||

|

- Steel Body frame - Steel Gears - Roll Slip Out arrangement for withdrawal of fully formed cylinders without deformation |

||

| Model: | BRM-24 | BRM-24L | BRM-24H | BRM-36 | BRM-36L | BRM-36H | BRM-48 | BRM-48L | BRM-48H |

| Roll Diameter (mm): | 50 | 64 | 76 | 50 | 64 | 76 | 50 | 64 | 76 |

| Capacity Width (mm): | 610 | 610 | 610 | 915 | 915 | 915 | 1220 | 1220 | 1220 |

| Capacity Thickness for M.S.: | 20 Gauge | 16 Gauge | 14 Gauge | 20 Gauge | 16 Gauge | 14 Gauge | 20 Gauge | 16 Gauge | 14 Gauge |

| Motor (HP): | 1 | 1 | 2 | 1 | 1 | 2 | 1 | 2 | 3 |

| Net / Gross Weight (kgs.): | 160 / 200 | 220 / 280 | 330 / 390 | 180 / 240 | 290 / 350 | 400 / 470 | 200 / 270 | 350 / 420 | 435 / 530 |

| Shipping Volume (m3): | 0.30 | 0.50 | 0.80 | 0.40 | 0.70 | 1.10 | 0.50 | 0.80 | 1.30 |

|

Standard Accessories: Electric motor and starter |

|

||

|

- Cast Iron frame reinforced by tie rods for machines having roll diameter of 25 & 50 mm - Steel Body frame for machines having roll diameter of 64 & 76 mm - Roll Slip Out arrangement for withdrawal of fully formed cylinders without deformation |

||

| Model: | BRS-12 | BRS-18 | BRS-24 | BRS-24L | BRS-24H | BRS-36 | BRS-36L | BRS-36H | BRS-48 | BRS-48L | BRS-48H |

| Roll Diameter (mm): | 25 | 25 | 50 | 64 | 76 | 50 | 64 | 76 | 50 | 64 | 76 |

| Capacity Width (mm): | 305 | 460 | 610 | 610 | 610 | 915 | 915 | 915 | 1220 | 1220 | 1220 |

| Capacity Thickness for M.S.: | 24 Gauge | 24 Gauge | 20 Gauge | 16 Gauge | 14 Gauge | 20 Gauge | 16 Gauge | 14 Gauge | 20 Gauge | 16 Gauge | 14 Gauge |

| Net / Gross Weight (kgs.): | 9 / 20 | 10 / 22 | 80 / 100 | 100 / 130 | 120 / 150 | 95 / 118 | 130 / 160 | 150 / 200 | 110 / 140 | 190 / 250 | 220 / 290 |

| Shipping Volume (m3): | 0.06 | 0.08 | 0.15 | 0.30 | 0.40 | 0.25 | 0.35 | 0.50 | 0.30 | 0.45 | 0.60 |

|

Hand Operated and Motorized Taper Bending Rollers - The roll taper conforms to bucket cone shape |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard Accessories with model TBR-18M, TBR-24M & TBR-30M: Electric motor and starter |

|

Maneklal

Global Exports |

|

TO OUR PAGE ON MACHINE TOOLS |