|

|

| Pedal Operated | Pneumatically Operated | Press Type | Contact Welders | High Precision |

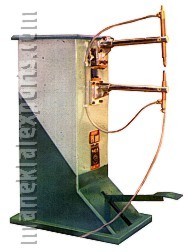

| Spot Welding Machines - Pedal Operated Rocker Arm Type |

|

Features:

Applications: |

|

Specifications: |

| Model: | MSP-6 | MSP-8 | MSP-10 | MSP-15 | MSP-20 | MSP-25 | MSP-30 | ||

| Rating @ 50% Duty Cycle (KVA): | 6 | 8 | 10 | 15 | 20 | 25 | 30 | ||

| Throat Depth (mm): | 350 | 400 | 460 | 460 | 460 | 460 | 460 | ||

| Nominal Throat Clearance (mm): | 220 | 220 | 220 | 220 | 220 | 220 | 220 | ||

| Welding Range (Thickness) | M. S. Sheet | Max. 2 x mm | 1.6 | 1.8 | 2.0 | 3.0 | 3.25 | 3.5 | 4.0 |

| Min. 2 x mm | 0.16 | 0.2 | 0.2 | 0.3 | 0.5 | 0.6 | 0.8 | ||

| Brass Sheet | Max. 2 x mm | 0.6 | 0.7 | 1.0 | 1.5 | 1.6 | 1.6 | 1.8 | |

| Min. 2 x mm | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.3 | 0.4 | ||

| Stainless Steel Sheet | Max. 2 x mm | 1.6 | 1.8 | 2.0 | 2.8 | 3.0 | 3.5 | 4.0 | |

| Min. 2 x mm | 0.2 | 0.18 | 0.2 | 0.3 | 0.3 | 0.6 | 0.8 | ||

| Min. available short circuit currents (KA) | 5 | 7 | 8 | 8 | 11 | 11 | 12 | ||

| Insulation Class: | F | F | F | F | F | F | F | ||

| Nominal Electrode Force - Approximate - (kgf.) | 75 | 100 - 75 | 100 - 75 | 100 | 110 | 110 | 125 | ||

| Electrode Stroke Max. (mm): | 40 | 40 | 40 | 40 | 40 | 40 | 40 | ||

| Mains Supply Voltage: | 415 | 415 | 415 | 415 | 415 | 415 | 415 | ||

| Phases (nos.) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Mains Supply Cable Size (Copper mm2): | 8 | 10 | 12 | 15 | 20 | 20 | 25 | ||

| Mains Disconnection Switch (A): | 15 | 20 | 25 | 30 | 45 | 50 | 70 | ||

| Delayed Action Fuse (A): | 15 | 20 | 25 | 30 | 45 | 50 | 70 | ||

| Water at max. temperature of 30oC (Liters/min.) | 2 | 3 | 3 | 3 | 3.5 | 3.5 | 3.5 | ||

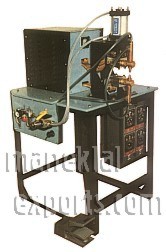

| Spot Welding Machines - Pneumatically Operated Rocker Arm Type |

|

|

|

|

|

Features:

Applications: |

|

Specifications: |

| Model: | MSP-10P | MSP-15P | MSP-20P | MSP-25P | MSP-30P | MSP-40P |

| Rating @ 50% Duty Cycle (KVA): | 10 | 15 | 20 | 25 | 30 | 40 |

| Throat Depth (mm): | 460 | 460 | 460 | 460 | 460 | 460 |

| Nominal Throat Clearance (mm): | 220 | 220 | 220 | 220 | 220 | 220 |

| Welding Range: S.S. / M.S. Sheet 2 x mm: | 2 to 0.2 | 3 to 0.3 | 3.25 to 0.32 | 3.5 to 0.5 | 3.75 to 0.6 | 4 to 0.8 |

| Max. available short circuit currents (KA) | 6 | 8 | 9 | 11 | 12 | 14 |

| Insulation Class: | F | F | F | F | F | F |

| Nominal Electrode Force - Approximate - (kgf.) | 100 - 75 | 100 | 100 | 110 | 110 | 125 |

| Electrode Stroke Max. (mm): | 40 | 40 | 40 | 40 | 40 | 40 |

| Mains Supply Voltage: | 415 | 415 | 415 | 415 | 415 | 415 |

| Phases (nos.) | 2 | 2 | 2 | 2 | 2 | 2 |

| Mains Supply Cable Size (Copper mm2): | 12 | 15 | 20 | 20 | 25 | 25 |

| Mains Disconnection Switch (A): | 25 | 30 | 45 | 50 | 70 | 80 |

| Water at max. temperature of 30oC (Liters/min.) | 3 | 3 | 3.5 | 3.5 | 3.5 | 4 |

|

|

| Spot / Projection Welding Machines - Pneumatically Operated Press Type |

|

|

Features:

Applications: |

|

Specifications: |

| Model: | MSP-15PR | MSP-20PR | MSP-30PR | MSP-40PR | MSP-50PR | MSP-75PR | MSP-100PR |

| Rating @ 50% Duty Cycle (KVA): | 15 | 20 | 30 | 40 | 50 | 75 | 100 |

| Throat Depth (mm): | 460 | 460 | 460 | 460 | 460 | 460 | 400 |

| Nominal Throat Clearance (mm): | 220 | 220 | 220 | 220 | 350 | 350 | 350 |

| Welding Range: S.S. / M.S. Sheet 2 x mm: | 3 to 0.3 | 3.25 to 0.32 | 3.75 to 0.6 | 4.0 to 0.8 | 4.5 to 1 | 4.5 to 1 | 6 to 1 |

| Max. available short circuit currents (KA) | 8 | 9 | 12 | 14 | 20 | 24 | 28 |

| Insulation Class: | F | F | F | F | F | F | F |

| Nominal Electrode Force - Approximate - (kgc.) | 1 - 2 | 1 - 3 | 1 - 4 | 2 - 4 | 2 - 5 | 2 - 5 | 2 - 5 |

| Electrode Stroke Max. (mm): | 40 | 40 | 40 | 40 | 50 | 50 | 50 |

| Mains Supply Voltage: | 415 | 415 | 415 | 415 | 415 | 415 | 415 |

| Phases (nos.) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Mains Supply Cable Size (Copper mm2): | 15 | 20 | 25 | 25 | 50 | 50 | 100 |

| Mains Disconnection Switch (A): | 40 | 50 | 75 | 100 | 150 | 200 | 250 |

| Water at max. temperature of 30oC (Liters/min.) | 3 | 3.5 | 3.5 | 4 | 4 | 4 | 5 |

|

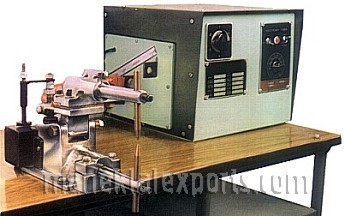

Contact

Welders for Contactors, Relays, etc. Pneumatically Operated High Precision Bench Mounted |

|

Features:

Applications: |

|

Specifications: |

| Model: | MCW-3H | MCW-10H | MCW-15H | MCW-30H |

| Nominal Rating (KVA): | 3 | 10 | 15 | 30 |

| Throat Depth (mm): | 150 | 150 | 150 | 150 |

| Approx. Working Height (mm): | 750 | 750 | 750 | 750 |

| Max. Upper Electrode Stroke (mm): | 25 | 50 | 50 | 50 |

| Vertical adjustability of lower electrode holder - up & down (mm): | 25 | 50 | 50 | 50 |

| Max. Available Currents (Short Circuit) (Amps): | 3000 | 8000 | 10000 | 12000 |

| Standard Cylinder Size (mm): | 50 | 65 | 75 | 100 |

| Max. electrode force (Kg/cm2): | 1.5 | 2 | 2.5 | 4 |

| Air Consumption @ 100 operations per minute (Ltrs/sec): | 1.62 | 7.5 | 7.5 | 13 |

| Cooling Water Required (Ltrs/min): | 3 | 5 | 10 | 15 |

| Mains Supply Disconnect Switch Rating (Amps): | 15 | 25 | 40 | 70 |

| Main Supply Cable Size (Copper mm2): | 8 | 12 | 15 | 25 |

| Net Weight (kgs.): | 140 | 170 | 200 | 270 |

| High Precision Spot Welding Machines - Electronically Controlled |

|

Features:

Applications: |

|

Specifications: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

*TPW - Thermally Permissible Welds |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Maneklal

Global Exports |

|

TO OUR PAGE ON WELDING MACHINE |