|

|

Automatic Ice Cream Cone Baking Machine |

Semi Automatic Ice Cream Cone Baking Machine |

| Automatic Cone Making Machine |

|

|

|

| Features: - ACG Series, Fully Automatic machines

deliver stacked cones / cups and moulded cones ready for packing |

Specifications: |

| Model: | ACG-12 | ACG-18 | ACG-24 | ACG-30 | ACG-36 |

| Number of Sets of Moulds | 12 | 18 | 24 | 30 | 36 |

| Electrical Load in kW (in case of heating by LPG Gas): | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 |

| LPG Gas Consumption (Kg. / Hour): | 5 - 5 | 8 - 10 | 12 - 15 | 14 - 16 | 15 - 20 |

| Approximate Dimensions (m): (without automatic stacking device) | 3.5 x 1.1 x 1.7 | 4.3 x 1.1 x 1.7 | 5.5 x 1.1 x 1.7 | 6.7 x 1.1 x 1.7 | 7.6 x 1.1 x 1.7 |

| Net / Gross Weight (kg.): | 3000 / 4250 | 4000 / 5250 | 5000 / 6500 | 6000 / 7500 | 7000 / 8500 |

| Shipping Volume (m3): | 13.00 | 18.00 | 25.00 | 36.00 | 45.00 |

|

|

|

Production Details: |

| Model: | ACG-12 | ACG-18 | ACG-24 | ACG-30 | ACG-36 |

| number of cones per hour for cone diameter of | |||||

| up to 29 mm (11 cones / mould): | 5250 cones | 7900 cones | 10500 cones | 13200 cones | 15800 cones |

| up to 32 mm (10 cones / mould): | 4800 cones | 7200 cones | 9600 cones | 12000 cones | 14400 cones |

| up to 36 mm (9 cones / mould): | 4300 cones | 6500 cones | 8600 cones | 10800 cones | 13000 cones |

| up to 41 mm (8 cones / mould): | 3850 cones | 5800 cones | 7700 cones | 9600 cones | 11600 cones |

| up to 47 mm (7 cones / mould): | 3350 cones | 5000 cones | 6700 cones | 8400 cones | 10000 cones |

| up to 56 mm (6 cones / mould): | 2850 cones | 4300 cones | 5700 cones | 7200 cones | 8600 cones |

| up to 68 mm (5 cones / mould): | 2400 cones | 3600 cones | 4800 cones | 6000 cones | 7200 cones |

Batter Depositor |

Stripping Device / Cone Ejector |

Gas Burner |

|

VIDEO OF AUTOMATIC ICE CREAM CONE MAKING MACHINE MODEL: ACG-18 |

| Semi-Automatic Cone Making Machine: |

Model: GE-500 |

Model: GE-500 |

Model: GE-500 |

| Features:

- Machine for manufacturing Ice Cream Cones, Cups and deep hollow Wafers. - Can also be used to make moulded sugar cones. - Depending on the diameter and type of the product, lower section of mould consists of three to six rows - Cones are automatically ejected into a container to be placed below the machine. - Machines can be easily operated by un-skilled workers with very basic training - Machine consists of One Mould which can produce only one type of cone, however, the machine is designed for quick change-over of mould to produce different type of cone. |

Specifications: |

| Model: | GE-500 |

| Electrical Connected Load: | 10 to 15 kW |

| Hourly Power Consumption: | 7 to 12 kW |

| Production per hour: | |

| For cone diameter 20 mm (146 cones / mould): | 4380 cones / hour |

| For cone diameter 24 mm (130 cones / mould): | 3900 cones / hour |

| For cone diameter 27 mm (116 cones / mould): | 3480 cones / hour |

| For cone diameter 30 mm (96 cones / mould): | 2880 cones / hour |

| For cone diameter 38 mm (70 cones / mould): | 2100 cones / hour |

| For cone diameter 42 mm (60 cones / mould): | 1800 cones / hour |

| For cone diameter 46 mm (44 cones / mould): | 1320 cones / hour |

| For cone diameter 56 mm (40 cones / mould): | 1200 cones / hour |

| Net / Gross Weight: | 500 / 600 kg. |

| Approximate Dimensions: | 1.3 x 1.1 x 1.6 m |

| Shipping Volume: | 2.5 m3 |

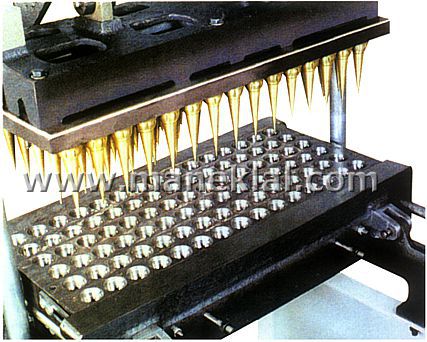

Die / Mould for Cup Cones |

Die in Semi-Open Position |

|

|

|

VIDEO OF SEMI-AUTOMATIC ICE CREAM CONE MAKING MACHINE MODEL: GE-500 |

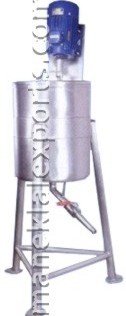

Batter Mixer Model: BM-60 |

Batter Mixing Machine:

- The Batter Mixer is suitable to mix

the liquid batter for Ice Cream Cones Specifications:

|

|

Maneklal

Global Exports |

|

TO OUR PAGE ON FOOD PROCESSING EQUIPMENT |